EMAE 355: Design of Fluid & Thermal Elements

This class focused on three group design projects of Fluid and Thermal Systems ranging from traditional power cycles to thermoelectric generation. On each project I used my Python numerical methods skills to enable efficient analysis and optimization of the design.

If you want to see the equations behind the any of the projects, click on the section heading to view a PDF of the project report.

Project 1:#

Supply appropriately conditioned CO2 to a bearing jacket to ensure smooth power cycle operation.

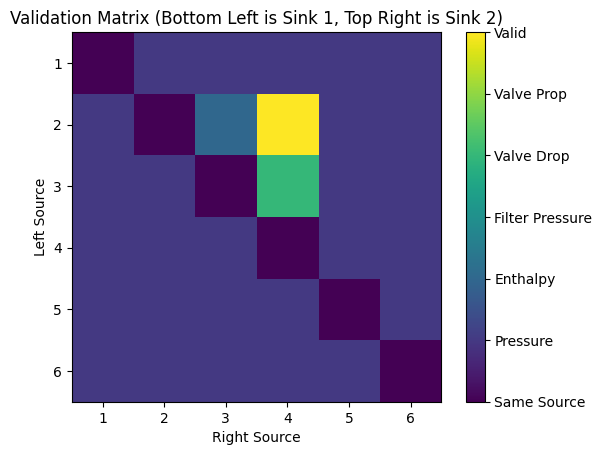

Our design extracted CO2 from two locations in the cycle and utilized two valves and a tee to ensure correct fluid conditions upon exit.

To determine the best pair of stations to draw, all possible combinations were examined:

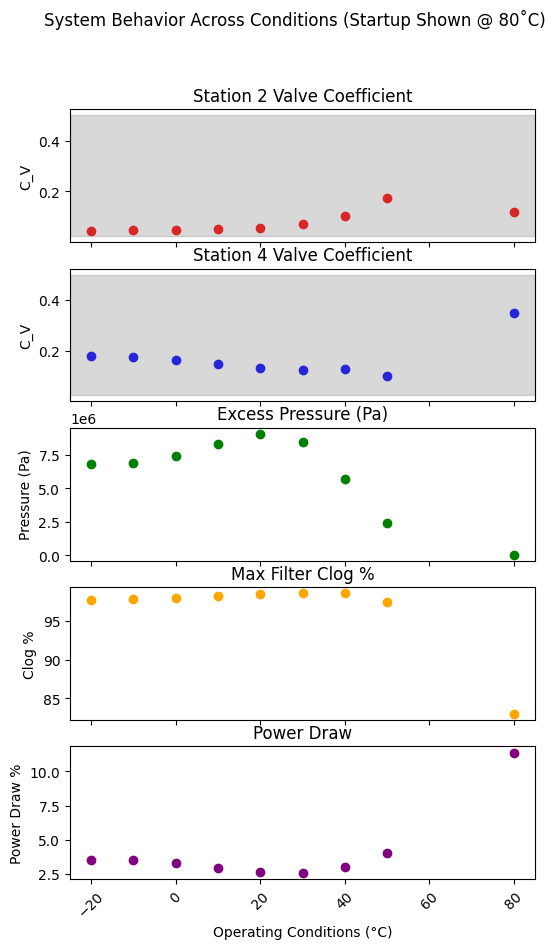

Performance across operating Conditions were demonstrated to meet component and system level requirements.

Project 2:#

Design a Agricultural Monitoring station capable of continuous operation through the growing season powered by a thermoelectric generator.

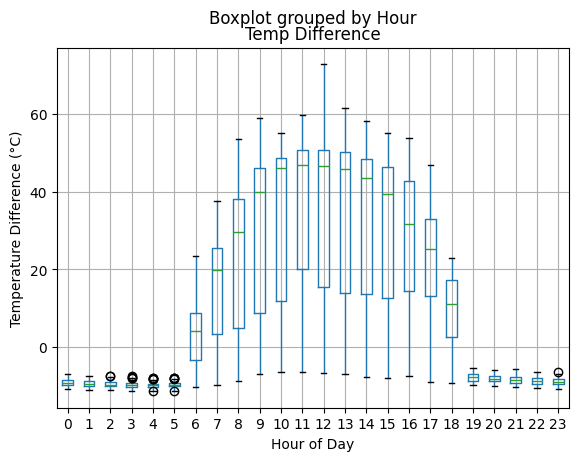

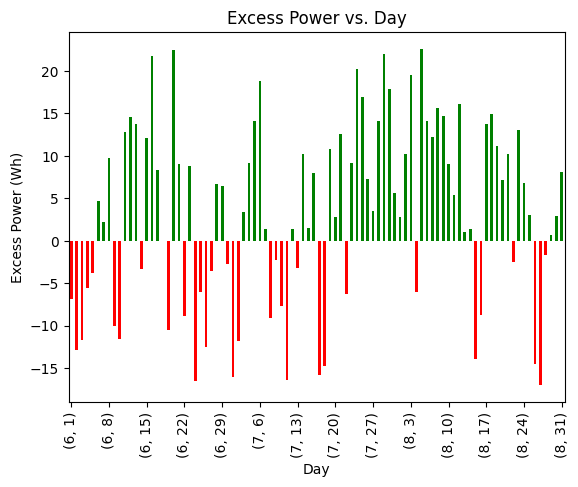

To ensure proper function throughout a growing season, the thermal electric generation was analyzed across multiple months of hourly thermal and radiation data.

This power analysis was further analyzed to appropriately size a battery to ensure sufficient capacity to shift power demand from sparse to plentiful hours.

Project 3:#

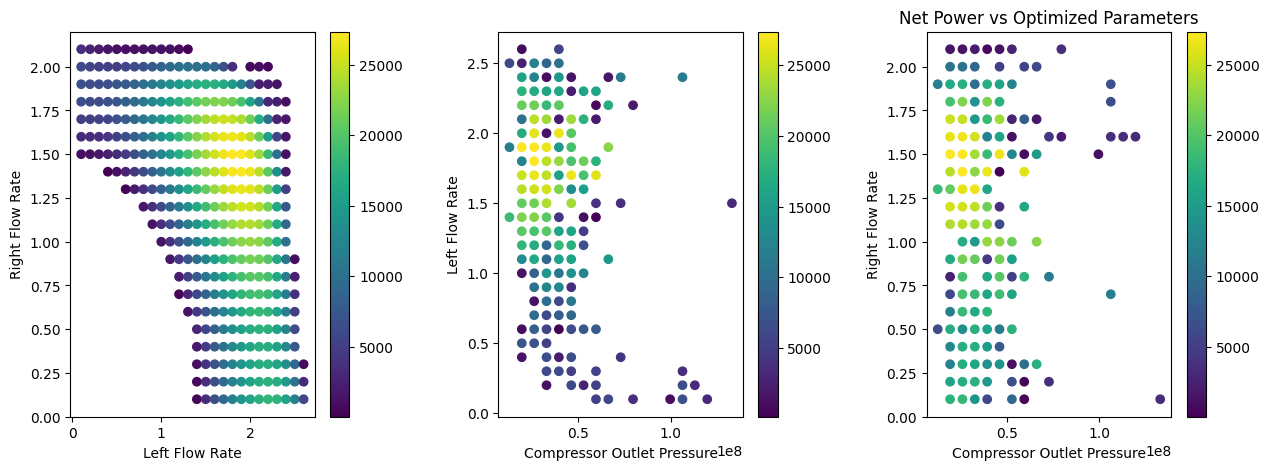

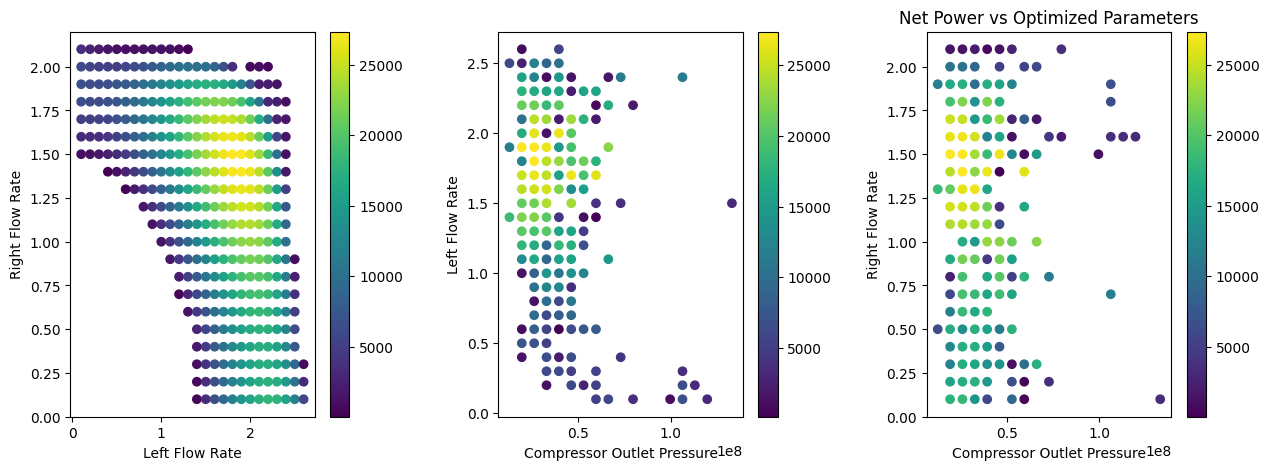

Design a CO2 Power cycle that sequesters in and extracts energy from a saline aquifer.

Compressor outlet pressure and the distribution of mass flow rate between the two aquifer outlets were optimized by sampling the parameter space and examining performant valid solutions.